Thermodynamic Engine Cycle Simulations

Thermodynamic simulations have been developed for spark-ignition engines. These simulations provide detail descriptions of the working fluid during the engine cycle. These details include the cylinder pressure as a function of crank angle. From the instantaneous cylinder pressure, the engine performance parameters may be determined as functions of engine design and operational variables.

These engine cycle simulations are available in both professional and instructional versions. The professional versions are developed for funded research programs to assist clients in understanding and improving existing engines, or for developing new engines. In addition to the typical computational outputs, these simulations also use the second law of thermodynamics to provide further insight on the engine processes.

The instructional versions of these simulations are used in our academic courses on internal combustion engines. These instructional versions of the simulations retain the important features necessary to illustrate the use of cycle simulations.

The major simplification of these simulations is the use of air as the working substance as opposed to complete descriptions of the working fluids.

Alternative Fuels

A number of research programs have been conducted on the use of alternative fuels for engines. Investigations of alternative fuels for engines are motivated mainly by the potential to reduce dependence on oil resources, and to minimize air pollution. Alternative fuels (and the related engine type) that have been investigated have included:

- Coal slurries for diesel engines

- LPG (propane) for spark-ignition engines

- Natural gas for diesel engines

- Hydrogen for spark-ignition engines

- Vegetable oils and animal fats for diesel engines

- Additives for diesel fuel

Diesel Engine Fuel Injection

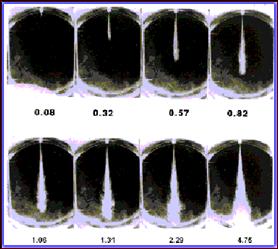

Detail studies on the injection of diesel fuel and coal-water slurries by traditional and advanced fuel injection systems have been completed. High speed movies and other diagnostics have been obtained as functions of injection system parameters and fuel specifications.

Experiments have been completed to characterize sprays from an advanced, electronically-controlled accumulator fuel injection system of a diesel engine. The sprays were injected into a pressurized chamber equipped with windows. High speed movies, fuel pressures and needle lifts were obtained as functions of time, orifice diameter, coal loading, gas density in the chamber, and accumulator fuel pressure.

Example conditions for these experiments included a 0.4 mm diameter nozzle hole, fuel pressure of 82 MPa (12,000 psi), and a chamber density of 25 kg/m3. For these conditions, the break-up time was 0.30 ms. Empirical correlations for spray tip penetration, cone angle and initial jet velocity were developed.

Technology Assessments

Technology assessments of engine concepts have been completed. These assessments include evaluations of technical and commercial feasibility, thermodynamic performance, and component integrity. Advantages and disadvantages of these concepts as compared to conventional power plants are developed. If required, more formal technical design reviews may be completed.

- Novel engine concepts that have been studied include:

- External combustion, reciprocating engine

- Rotary-Vee IC engine

- High-performance marine diesel engine

- Free-piston, impulse combustion engine

Copyright © 2001 – 2012 E3 (Engines, Emissions, Energy) Research Laboratory, Texas A&M University Department of Mechanical Engineering, College Station, TX 77843-3123, Phone (979) 845-4705, Fax (979) 845-3081